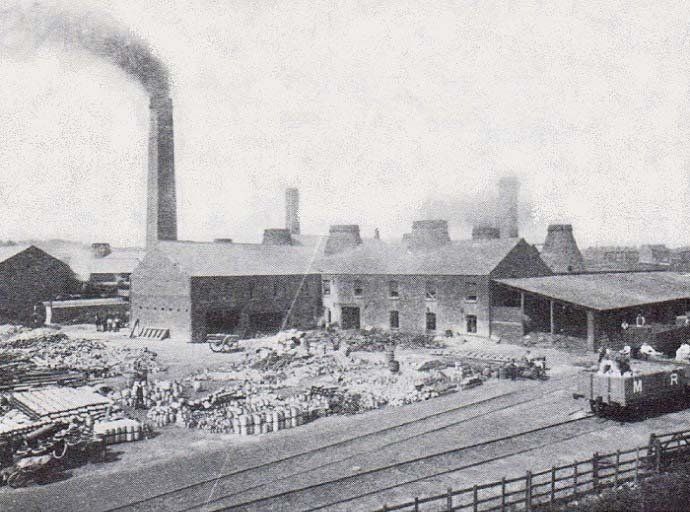

A view of the Bottom Pottery from the MIdland Railway. A siding runs directly into the yard.

Pearson Potteries 1899 - 1932Brampton and Whittington

Continued from Pearson 1810-1898 More views Index & Maps:

The next 2 photos are from, 'An Illustrated Guide to Chesterfield and its Surroundings', c1899.

The Top & Bottom potteries with the brickyard cover 6 acres & 620 hands are employed.

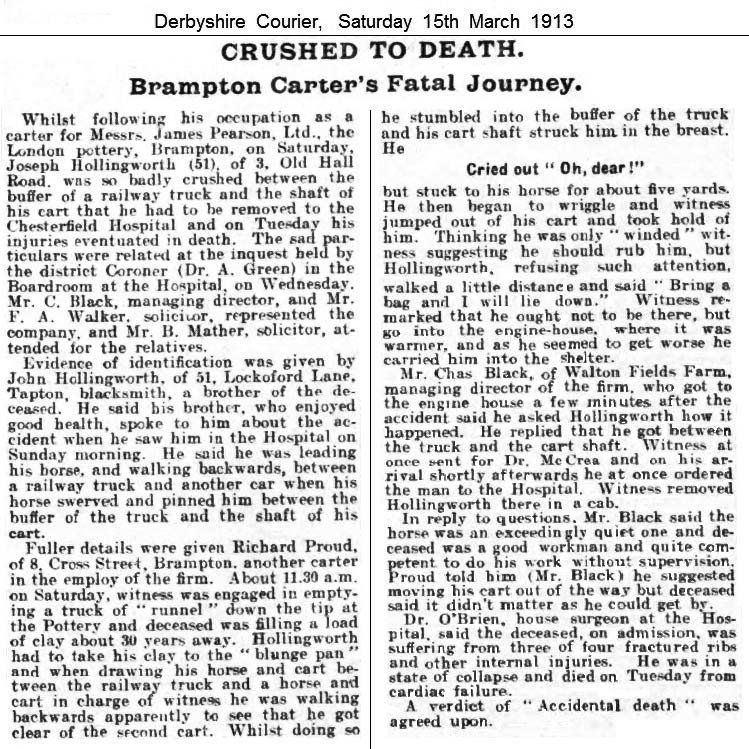

Derbyshire Times Saturday 5th August 1899 Employees going AWOL

BRAMPTON WAKES, AND ITS CONSEQUENCES

There were 3 summonses entered for Thursday's Chesterfield Borough Court arising out of holidays taken after the Brampton Wakes. Mr. James Pearson was the complainant, & the defendants were Walter Bower, of Alma Square; Thomas Wetton, of Prospect Street; & Clara Bennet, of Alma Square; who were summoned under the Employer's & Workmen's Act for having absented themselves from work without giving the customary seven days notice.

The case of Clara Bennett was taken first, & Mr. Black, in the employ of Mr. Pearson, said that the defendant was employed by the Pottery up to June 30th. The Pottery then ceased work for Brampton Wakes, & they had to stand a week much against their wish. Bennett gave no notice & had not yet returned to work.

In answer to the Bench, Mr Black said if they dismissed a person at a moment's notice, unless it was for insubordination, they would pay a week's wages..........

A witness said he could produce dozens of 7 day notices received from employers & swore that it was generally understood at the Pottery.

Bennett was fined 2s 6d & ordered to pay damages of 2s 6d, & costs. Walter Bower had the same judgement but the case against Wetton was withdrawn.

The Bench intimated that in their opinion printed rules should be posted up in the Pottery showing what notice must be given on either side.

Sheffield & Rotherham Independent, Thursday 5th July 1900

WHITTINGTON URBAN.

- A letter from the workmen employed at Pearson's Pottery, Whittington Moor, was read, asking that gas lamps might be placed on Pottery Lane. It was decided to put down one lamp.

Sheffield Daily Telegraph, Thursday 16th August 1900 Another Death

BURIED IN A CLAY PIT NEAR CHESTERFIELD.

A fall of "bind" occurred yesterday at a clay pit at Walton, belonging to Mr. James Pearson, colliery owner & earthenware manufacturer, completely burying a man named Richard Buxton, aged 45, of Britannia Street, New Brampton. He died from suffocation.

Derbyshire Times 1st December 1900 Horseplay gone wrong

[Summary]

Horseplay at a Whittington Moor Pottery.

Jars as Missiles.

Horseplay took place at Whittington Moor Potteries on November 21st which culminated in Thomas Richard Bembridge (16) being charged on Saturday with assaulting Alice Boot. Boys were throwing pots around at girls. Alice Boot entered a room & got hit on her lip & nose, with a one pound jar. Mary Ann Vardy (16) said the defendant was throwing a jar at Anne Robinson & he hit Alice by mistake. Defendant was fined 10s & costs.

The

1901 Census brings, at 9 Abercrombie Street, Elizabeth Pearson, Theo's widow, as head, & living on her own means, with niece Kate, daughter Annie G., son Theo. & nephew Arthur Pearson; the latter 2 being earthenware manufacturers. Her sons Tom & Frank, both unmarried, living at 44 Victoria Street, Chesterfield. Frank is now a vet & employer & Frank a Dispenser. Johnson Pearson moved out after his marriage & lives on the High Street, Whittngton with his wife Mary & son Theophulis.

James Pearson is still at the Manor House in Brampton with his wife Harriet & mother in law Christiana Towlson; but now he has a son James Alan, & a daughter Doris Christine.

Life still goes on at the Potteries:

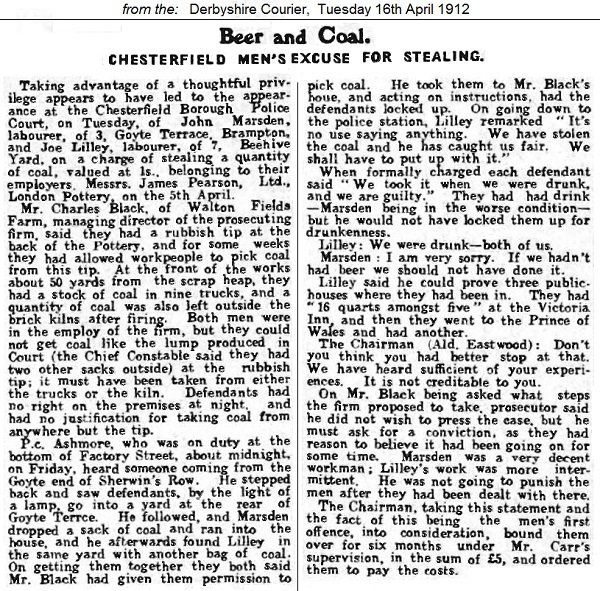

Derbyshire Times, Wednesday 28th May 1902 Whittington Potteries: A 'perk' of the job became too expensive....

STEALING COAL.

A COMMON PRACTICE AT PEARSON'S POTTERIES.

Robert Lee was charged at the Chesterfield Sessions, on Saturday, with stealing 20 lbs of coal, value 3d, the property of Messrs. Pearson & co. Whittington Moor Potteries, Chesterfield, on the 7th May. Mr. M. Bunting prosecuted on behalf of Pearson & Co.

Robert Lee was a colliery banksman, & on the day in question he was engaged by Messrs. Pearson's Pottery in stacking coal. When he left work on that afternoon P.C. Vardy saw that his pockets were bulky; & on searching him found they were full of coal.

The value of coal was very small, but, as the practice was becoming very common, Messrs. Pearson decided to have a stop put to it. That was the reason given for the prosecution.

Defendant pleaded guilty & was fined 10s.

Derbyshire Times Wednesday 17th September 1902

James Pearson still earning a penny..

STABLING Accommodation to Let, situate in Bobbin Mill Lane, Brampton; rent moderate.

- Apply James Pearson, Oldfield Pottery, Chesterfield.

Manchester Evening News Monday 13th April 1903 Messing around caused death at Whittington Pottery

GIRL KILLED AT POTTERY

An inquest was held at the Chesterfield Hospital on Saturday, on the body of Kate Tatlow (16), pottery hand, employed at Pearson's Pottery, Whittington Moor.

Mary Baker, a clay ball maker, said the deceased, who had been at the works 5 weeks, went into the loft on Thursday afternoon, & it was suggested she should have a ride round a revolving cupboard. The deceased had no right to get on the cupboard & witness had never known it before. It was turned by a girl named Briggs. There was no machinery attached to the cupboard which was used to put moulds on.

Priscilla Fisher, another pottery hand, saw the cupboard revolve, heard a bang on looking saw deceased fall from the top of the cupboard to the floor.

Dr. Radcliffe said death resulted from fracture at the base of the skull & spine.

A verdict of accidental death was returned.

Sheffield Daily Telegraph Friday 16th December 1904 A death prevented...

ACCIDENT AT WHITTINGTON MOOR.

On Wednesday a serious accident occurred to a man named Collins, who worked at the Pearson's Potteries, Whittington Moor. Collins went to oil certain machinery, & the morning being very wet, he had a sack over his shoulders. The machinery caught the sack, & took the man round, & but for the promptitude of the engine-man he would probably have been killed. As it was he sustained a broken arm, & an ugly scalp wound. He was removed to the Chesterfield Hospital.

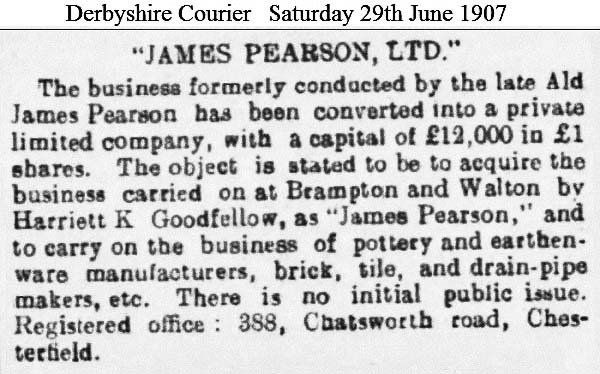

Alderman James Pearson died on

Friday the 5th May 1905

after a very short illness: His death came as a shock to many. He had been to a meeting of the Education Committee, of which he was a member, on the previous Friday. On the Sunday he complained he was unwell & Dr. Goodfellow was called. He later had an attack of pneumonia & Dr. Burgess, a specialist was called. On

Thursday the 4th

oxygen was administered, but unfortunately 2pm on Friday 5th he passed away.

In his will, dated

15 February 1896, he leaves,

"all my real and personal estate of every description unto my dear wife Harriet Helen Pearson absolutely". The Will was proved

3rd July 1905. One of the witnesses to his Will being James Anderson Goodfellow, of Old Road, Chesterfield, Physician & Surgeon.

2nd April 1911

sees Harriet Helen & husband James Anderson Goodfellow living at Grove House, Ashover, near Chesterfield. James is a 'medical practitioner', although by then he had given up practice & was in bad health. With them is Doris Christine Pearson, Harriet's daughter by James Pearson: Harriet's son by James, James Alan Pearson, is away at preparatory school in Worcestershire.

Elizabeth Pearson, Theo's widow, is still at 'Pine Tree Bank', 9 Abercrombie Street, Chesterfield, as head of the family; she lives there until her death, aged 85,

on

June 15th 1914.

With her is her son Theo., daughter Annie Jervis, niece Kate, & nephew Arthur Glossop Pearson. Also there is Elizabeth's granddaughter Gertrude Kitty Pearson, daughter of her son Frank Bernard Pearson & Alice Mabel [nee Harrison] Pearson who married in the 3rd quarter of

1895.

Frank Bernard & Alice Mabel Pearson are living at Victoria Street, Chesterfield. Elizabeth's son Tom is still unmarried & living at Bole Hill, Barlow, where he was a dispenser for a chemist.

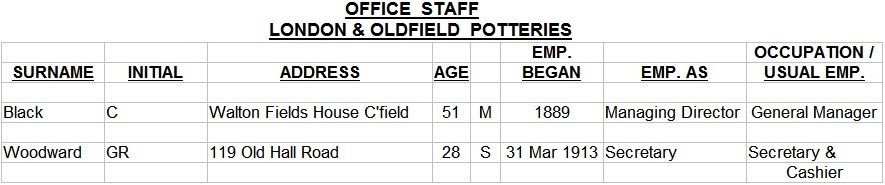

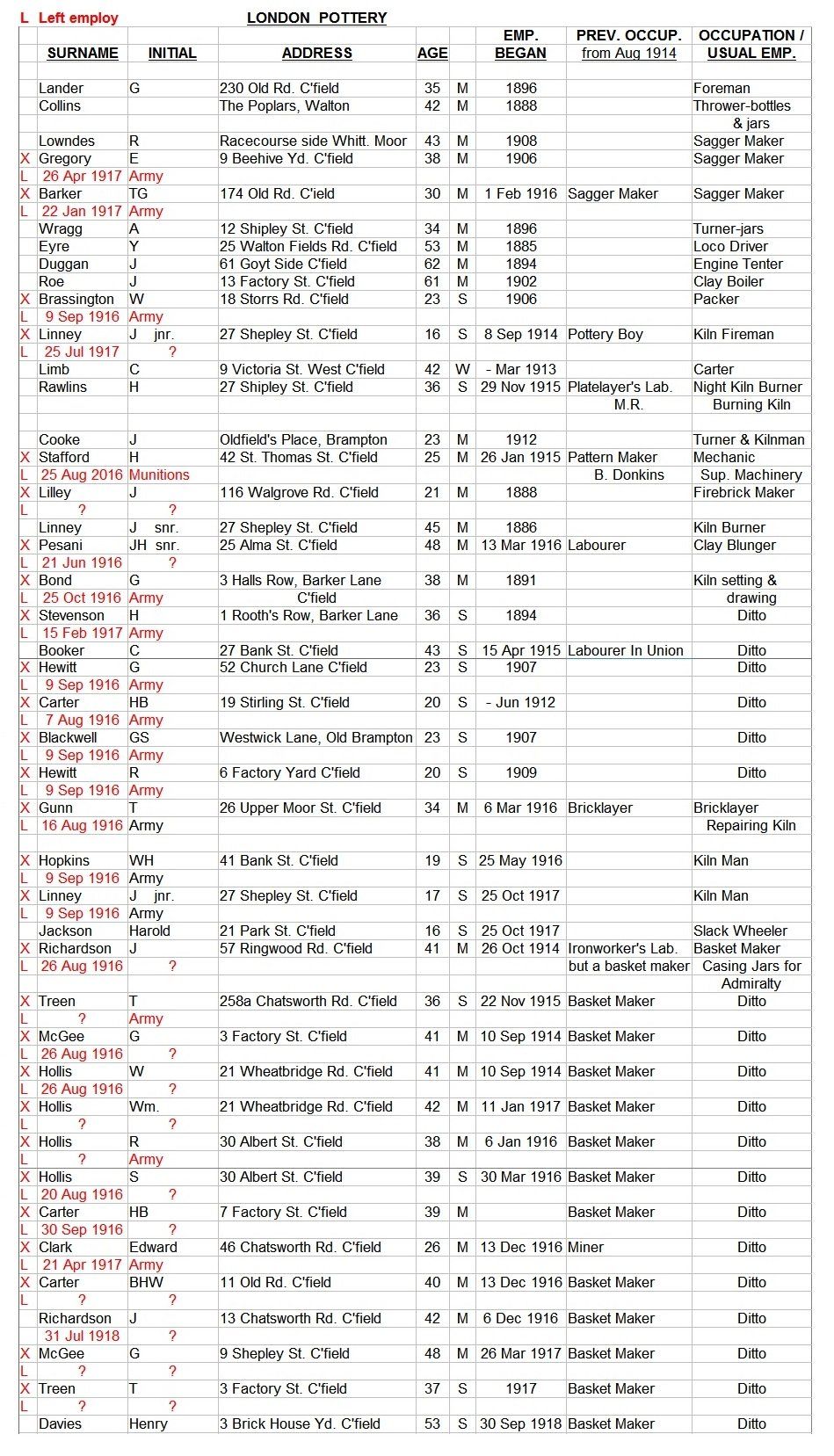

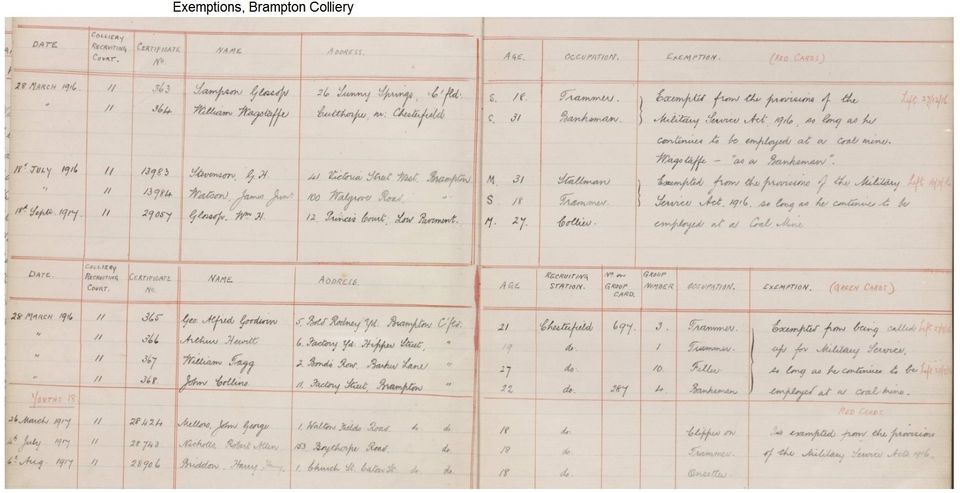

Military Service Act 1916. Conscription.

The Government introduced the Military Service Act on

27 January 1916. All voluntary enlistment was stopped. All British males were now deemed to have enlisted on

2 March 1916 if they were aged between 19 and 41 and resided in Great Britain (excluding Ireland) and were unmarried or a widower on

2 November 1915. Conscripted men were no longer given a choice of which service, regiment or unit they joined, although if a man preferred the navy it got priority to take him. This act was extended to married men, and the lower age dropped to 18, on 25 May 1916.

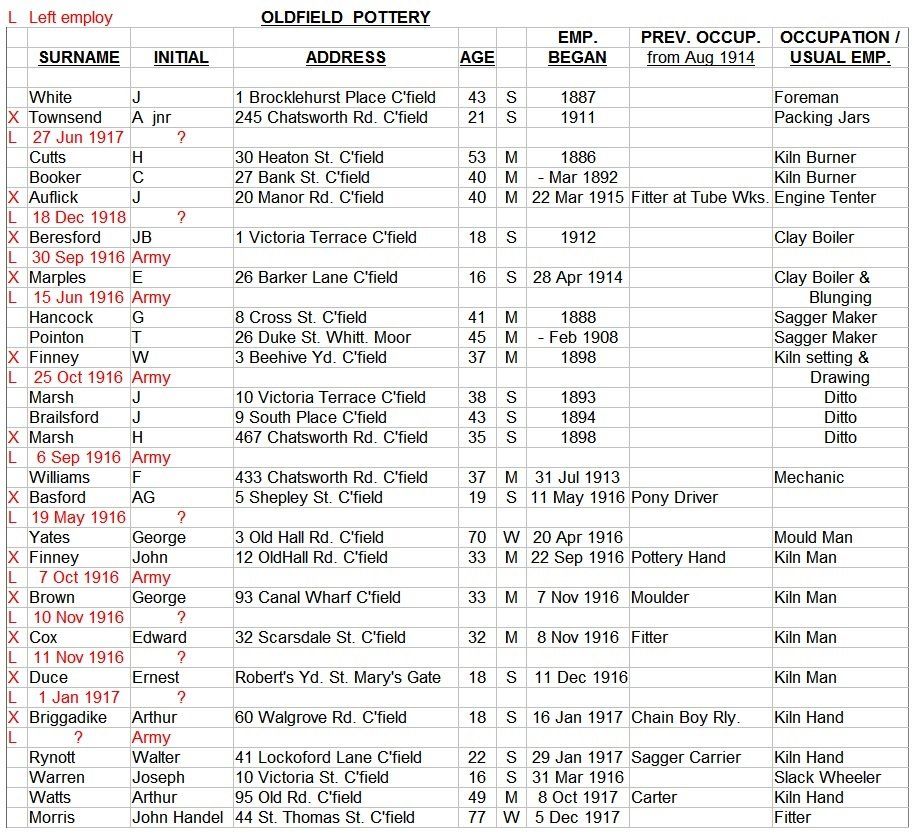

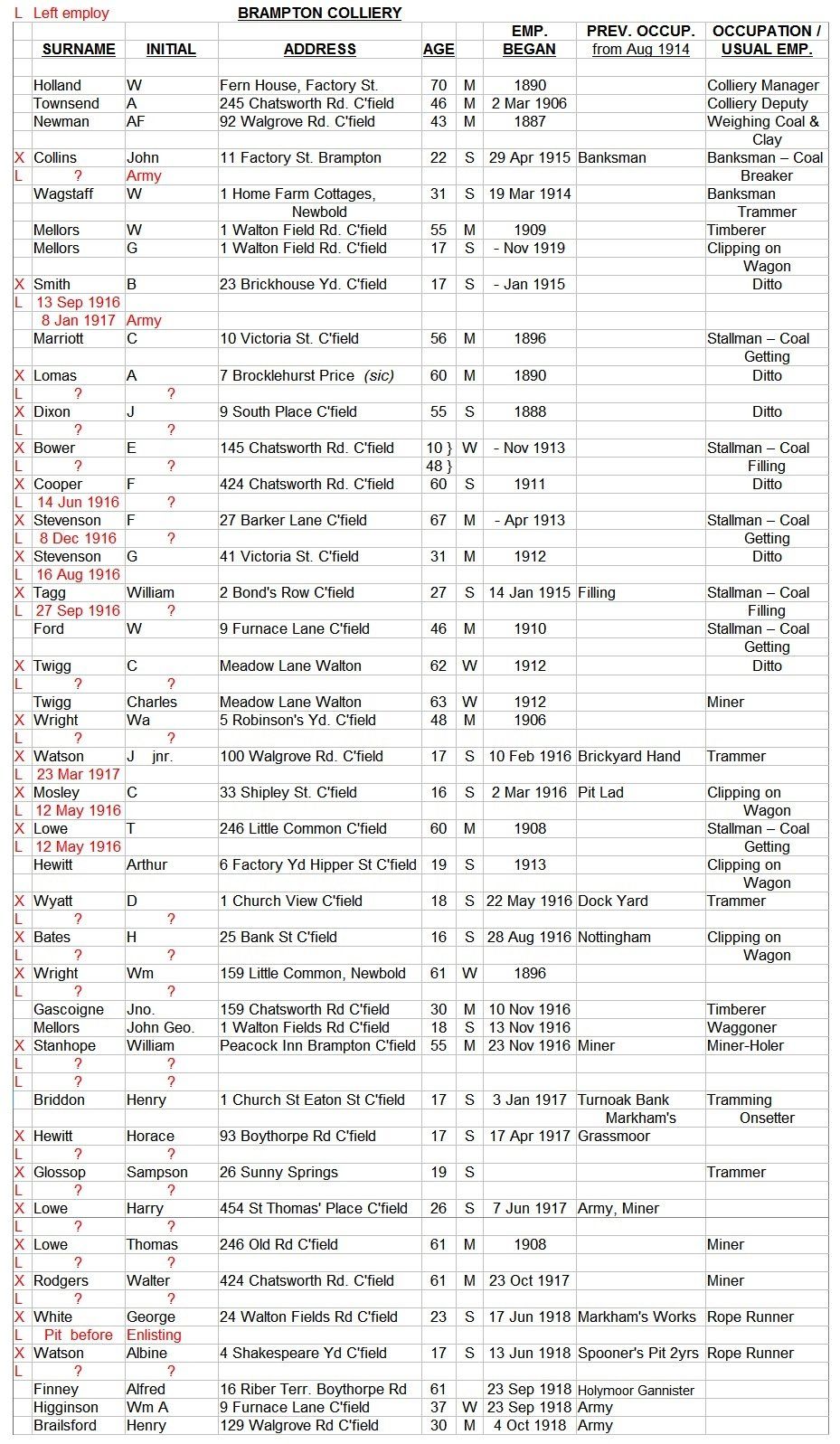

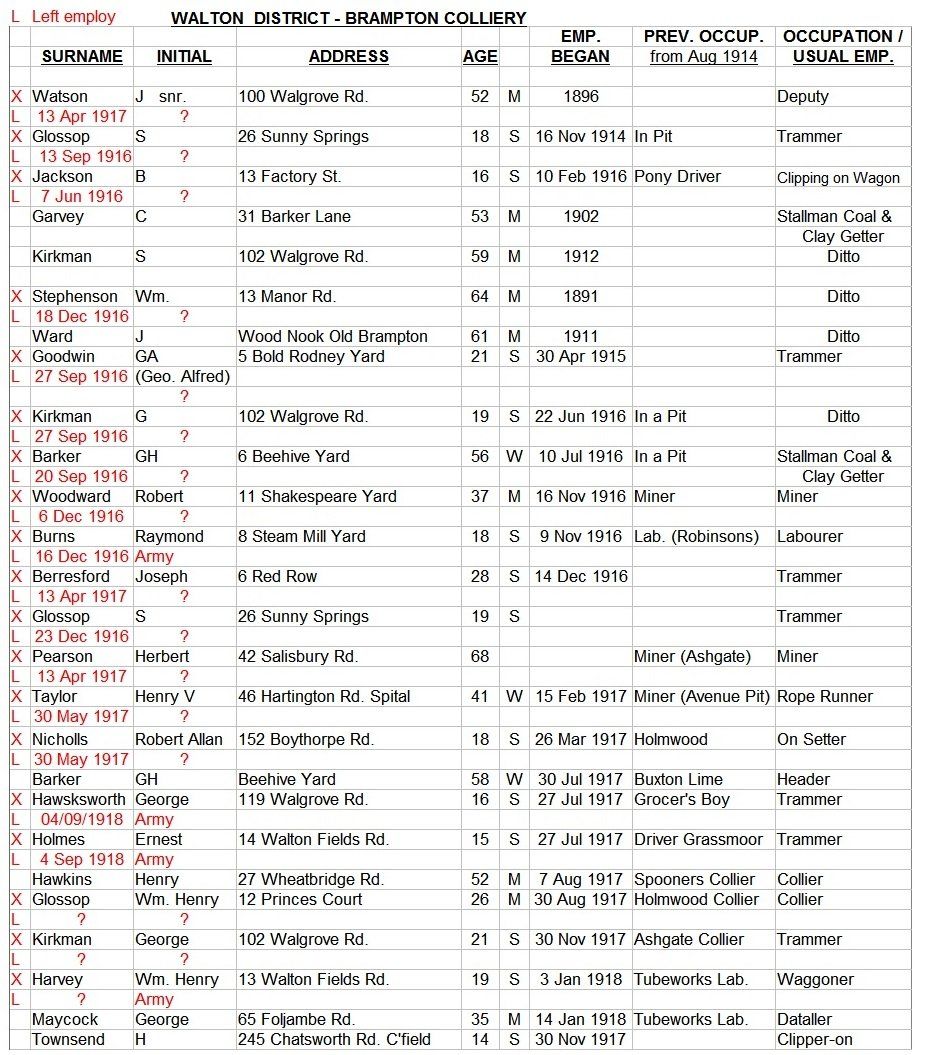

Employers were to keep registers or information on their employees: This included Messrs Pearson & Co. Whittington Moor & James Pearson Ltd., Brampton, potteries.

The following are registers of all male employees over 16 years of age at James Pearson Ltd.

(There are more details I haven't noted, that can be found in the Local Studies dept. of Chesterfield Library.)

Even if you were doing a job for the govt. it didn't mean you'd be exempt....

Derbyshire Courier Saturday 16th September 1916

Summary

140 DEBADGED MEN

Tribunal Contest at Whittington.

Pottery Firm's Appeal.

A meeting of Whittington & Newbold Tribunal Board lasted upwards of 2 hrs when Messrs. Pearson & Co. Whittington Moor, objected to the amount of men the Military Representative, Mr. Eustace Edmunds, said were eligible for the services.

Messrs Pearson & Co.'s position was that:

*

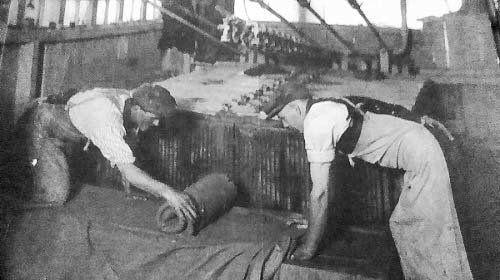

Only 20 out of the 140 debadged men were not on govt. work. The whole of the bottom pottery were engaged on govt. work & the top pottery were engaged on jam jars. As winter was coming then the top pottery may also be needed for govt. work.

*

Over 58% of men had already joined up - although Mr. Edmunds responded that other firms had had more than that joined up & had made sacrifices.

*

Taking 70 men out of the 140 men as Mr. Edmunds wanted would be too drastic & they would not be able to fulfill the order for the govt. There were different stages & depts. in the pottery business with different men doing a specific task, so making one jam jar or a hundred the process was the same.

*

The amount of workforce had been a consideration when they had received the order; & they were given the maximum contract. The men are needed to fulfill the order from the admiralty

*

If the men were in an established certified occupation, & if the military rep. did not object within 5 days then they would be granted a certificate of exemption. No objection had been offered.

The meeting ended with Mr Edmunds being given extra time to object to the exemptions.

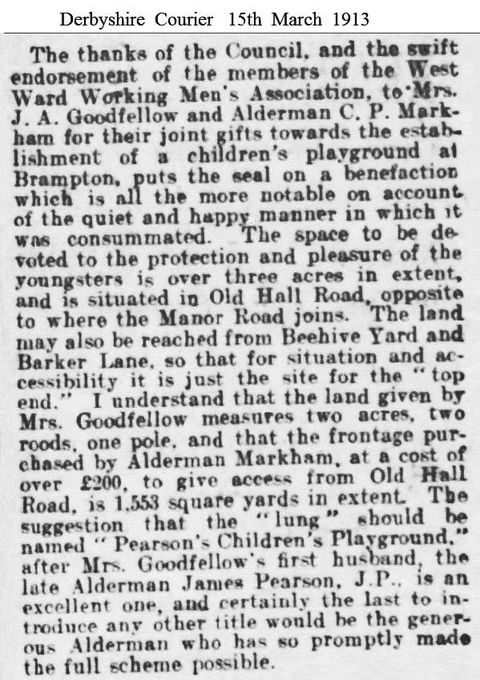

Derbyshire Courier, Saturday 24th August 1918 Vandalism at the London Pottery

IN THE CLAY HOLE.

WARNING TO TRESPASSERS AT BRAMPTON.

A good deal of wanton damage has been committed on the premises of Messrs. James Pearson, Ltd., pottery manufacturers, Brampton; & at the Chesterfield Borough Court, on Monday, three youths were summoned for damaging a clay-hole to the amount of 5s. The defendants were Alfred Smith, 31 Shepley Street; James Collins, 11 Factory Street; & Albert Hill, 59 Shepley Street.

Mr. J. A. Hopkins prosecuted, & explained that so much damage had been done that the firm had been compelled to institute proceedings. Besides the damage in the clay-hole, youths had been found on the roof of the premises, & windows had been broken & lead removed.

George Lander, foreman at the London Pottery, said that on 8th August he found Smith 'holing' with a pick in the clay-hole, & about a ton of clay was ready to fall when rain came. It would be necessary to remove the loose clay before brick making could be resumed. Smith said the pick belonged to Hill, & Collins was looking on.

Collins said they did not think they were doing any harm. Scores of people were there every night, & nothing was said to them. Hill, who did not appear,was fined 15s., & Smith & Collins has each 12s. 6d. to pay. Ald. G. A. Eastwood gave warning that any future cases of trespass would be very smartly dealt with.

Theophulis Pearson, son of Johnson Pearson, married Violet Mary Short, second daughter of Samuel Edward Short, Accountant & Alderman: It was registered in the December quarter of

1922

in the District of Chesterfield. They lived at Red House, Stonegravels until Theo's. death in

1959;

then Violet moved to 691 Brookside, Chesterfield. They had no heirs. Violet was a Director of Pearson & Co. (Chesterfield) Ltd. & for a time acted as Welfare Officer fro the employees.

Annie Jervis Pearson was still living at 9 Abercrombie Street in

1922, & will until her death.

The Oldfield Pottery of James Pearson Ltd. was advertised for sale.

Sheffield Independent, Wednesday 31st January 1923

WORKS FOR SALE

CHESTERFIELD .- DISUSED POTTERY for Sale; are (Land and Works) nearly 3 acres; valuable frontage to two main roads; fireproof construction, gas, water, electricity; Midland Railway extension into works; river included; Boiler and Engine can be purchased; immediate possession; could be adapted for almost any purpose, foundry, engineering motor works, laundry, bakery etc. -For further particulars apply James Pearson, Ltd., Oldfield Pottery, Brampton, Chesterfield. 593

On the

9th November 1928 Frederick Stanton Short, Theo. Pearson's brother in law, was appointed Secretary at Pearson & Co. over at the Whittington Potteries.

Trouble at the London Pottery

Nottingham Evening Post Thursday 27th February 1930

£2,000 Damage at Pottery Works

A disastrous fire broke out yesterday at the London Pottery, Goyt Side, Brampton, of Messrs. J. Pearson Ltd., Chesterfield, damage being done to the extent of £2,000. This was covered by insurance. When the Borough Brigade arrived the flames, 20ft. high, were leaping into the air from a shed used as a warehouse & for packing purposes.

The roof was a mass of flames, which burned with such fury that it was 2 hours before the fire was mastered.

A second engine was sent for, & but for the effective work of the brigade the fire would have undoubtedly spread to the adjoining works. Two railway wagons were damaged by the flames.

A fireman, A.C. Abbott, had to be treated for a crushed foot.

Derby Daily Telegraph Wednesday 8th April 1931

Death of Johnson Pearson Summary

DERBYSHIRE ALDERMAN LEAVES £53,000

BEQUESTS OF MR. JOHNSON PEARSON

Alderman Johnson Pearson died on the 25th June 1930, aged 72. He left £56,260 10s 8d, with net personality of £47,846 13s 3d. Probate of his Will was granted to his son Theophulis Pearson. He leaves £400 a year for life to his cousin Annie Jervis Pearson.

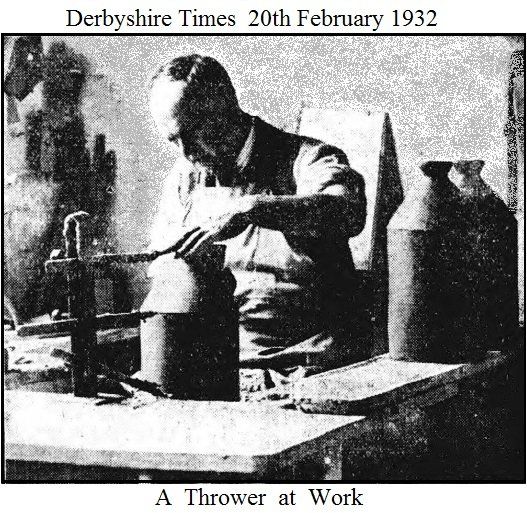

Pottery Making, a summary.

Text & images from the

Derbyshire Times &

Terry Hubbard - a 4th generation pottery worker at Pearsons.

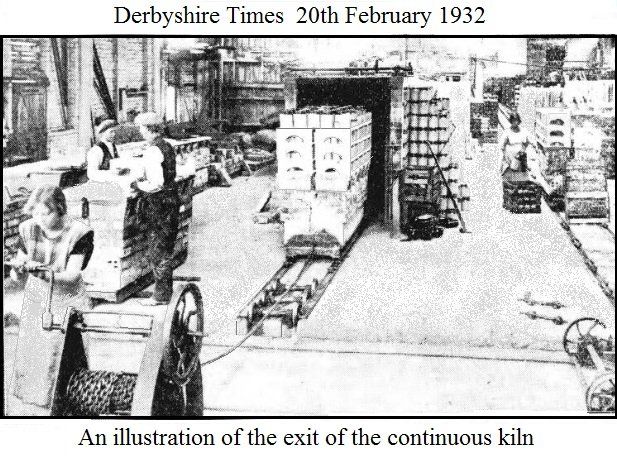

Derbyshire Times, Saturday 20th February 1932

from:

Messrs. Pearson & Co. Whittington.

Clay

Clay used in the pottery is dug from Newbold, but for the finer work special clays come from Devonshire & other parts of England. The clay, when brought to the pottery, looks like lumps of slate. It is rock-like & the first process of manufacture is to reduce it to a workable condition. It is ground & reduced to a mud then pushed through an extremely fine mesh. It is then ready for the potter.

Glazing

The potter takes rocks of components suitable for glazing material & puts them in a revolving drum. The action forms the glaze: Into this the earthenware is dipped before baking. The quality of the glaze differs with the nature of the article on which it is to be applied. One of the technical difficulties a potter has with glazing is when the glaze 'crazes' during baking, or subsequently, & fine lines or cracks appear under the glaze. It's particularly noticeable in coloured tiles & if very difficult to prevent.

In the

Testing Department finished articles are sounded. Each article is tapped with a light piece of metal; if it sounds true & gives a musical ring then it is passed, otherwise it's scrapped.

Messrs. Pearson's new department is turning out pottery in the old syles of the Toby jug & cottages, but also articles in more modern design; among them motor-car mascots, lamp shade stands, ash trays & candlesticks.

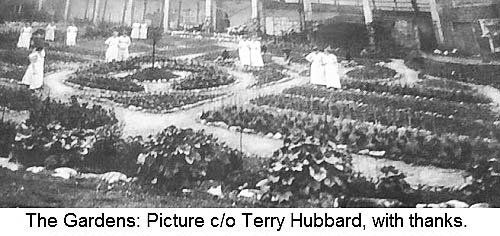

Unexpectedly for a manufacturing plant Messrs. Pearson have a very fine flower garden which they are proud of. They are also proud of the gardener, a Mr. Goucher, who is over 70 years old & has worked for the firm since his youth. Mr. Goucher is an expert joiner & his work may be seen in the handsome paneling of the firm's offices.

Messrs. Pearson's products are exported to all parts of the world. & make all kinds of domestic pottery including a fire-proof stoneware known as 'Krusta'.

Later that year the Pearson Pottery at Whittington was severely damaged by flood.

Derbyshire Times 28th May 1932

FLOOD SCENES. GREAT DAMAGE IN DERBYSHIRE

“…..Private dwellings and large factories in the low-lying portions of Chesterfield all suffered, the ground floors being covered in a depth of several feet.....

…..In nearly every instance the flood had left its mark on the walls while floors were covered with a mixture of gravel & slimy mud.....

Pearson's Potteries of Whittington Moor suffered considerably. Mr Short, the secretary to the company..... said it was the worst flood they had ever experienced, and this was the second occasion in eight months that their premises had been flooded on the ground floors.....

…..the glazing and throwing departments revealed an almost chaotic state of affairs. The water had invaded the rooms to a depth of 4ft 3 inches and had left their departments like shambles. Various articles of pottery, which had been left on rows on wooden racks, prior to being glazed and placed in the kilns, were reduced to thick oily clay. None of this could be salved, as the various colours of the ware of white, red and black, had all run into each other. There were hundreds of these articles ready for the kilns, and now they are totally destroyed. The pottery clay etc. was inches thick on the floor while the boards or shelves, on which the pots had been placed, lay about the room in all sorts of positions and at all angles, just as the storm waters had left them..... Thirty-five sacks of plaster of Paris were destroyed.

Both the TUNNEL KILNS WERE FLOODED; one to a depth of four feet, and the other to a depth of three feet. They were in use when the water entered, the temperature of the kilns, which are brought to a white heat, being 1,250 degrees Centigrade! There was a deafening hiss as the water gradually crept along the tunnels of the kilns, and the heat, which was slowly being pushed into a confined space, was terrific. At one end a wooden crate floated slowly near the entrance to one of the tunnels, and this caught fire, the flames being quickly extinguished.

Mr Short said that it was 6.00 am on Sunday when the day shift were on duty that matters commenced looking ominous, and by 7.30 am the water had crept inwards and onwards like a voracious serpent, to a depth of four feet. The pumps were kept working as long as possible, but these were of little avail against the hundreds of gallons of water which came rushing over the banks of the river, shortly after 7.0 o'clock. “Your paper should raise an outcry about these rivers not being deep enough,” said Mr. Short indignantly. “That's the whole trouble. The rivers are not deep enough to carry the water away, and the temporary bridges are more a hindrance than a help in times like these, but the authorities who control them won't do anything in the matter.”

Mr Short estimated that the river had risen 10 feet, and added that employees of the firm had noticed the carcasses of pigs being carried swiftly down with the raging torrent of water.”

Continued 1933 - 1994