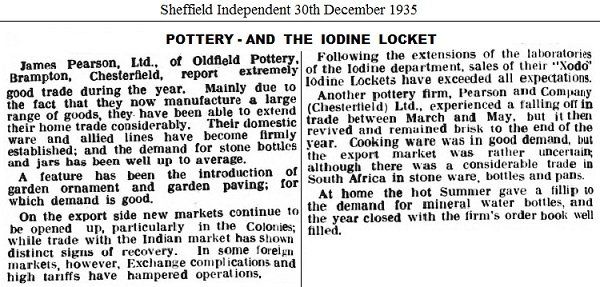

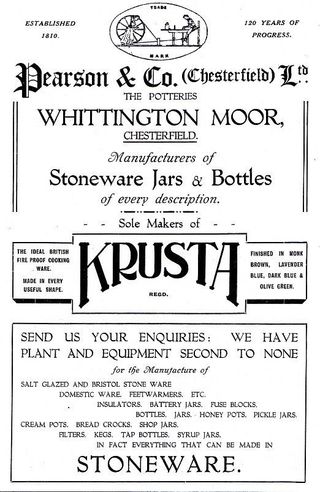

By 1935 both the Whittington & Brampton Pearson Potteries were advertised as doing well.

Pearson Potteries 1933 - 1994Brampton and Whittington

Continued from Pearson 1899-1932

Meanwhile over at Brampton experiments were coming to fruition.... iodine health products

Derbyshire Times, 18th February 1933 James Pearson Ltd Oldfield Pottery

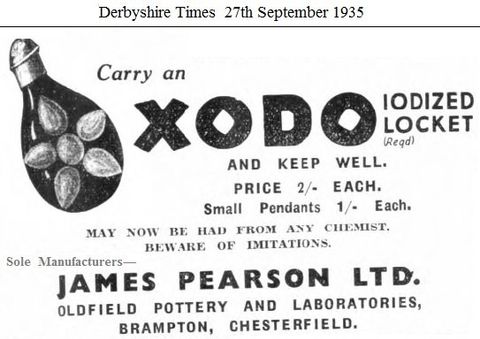

Dr. J.A. Goodfellow, managing director of James Pearson Ltd. has, after years of experimenting with iodine, & with his knowledge of the pottery process, created a way for iodine to be harnessed & slowly released, via lockets, buttons, brooches & candles etc. His work began in 1922 when he started to research goitre, which was common in Chesterfield & district.

The new department at the Oldfield Pottery has been working at full pressure to fulfill large orders of the product. The 'magic charms' received tremendous publicity during the influenza epidemic, throughout the Country & from abroad.

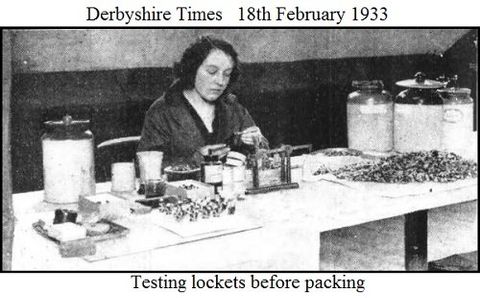

The Testing

In 1931 a special clay was prepared with the right amount of required porosity so as to slowly emit the iodine. Dr. Goodfellow made a number of lockets filled with iodine which were part glazed – the iodine being released from the un-glazed part, & they were worn from 3 months to 18 months. Dr. Kenneth Fraser, the County Medical Officer for Cumberland, distributed 650 lockets throughout 54 schools, & the outcome to the testing was that they were seen as beneficial to health.

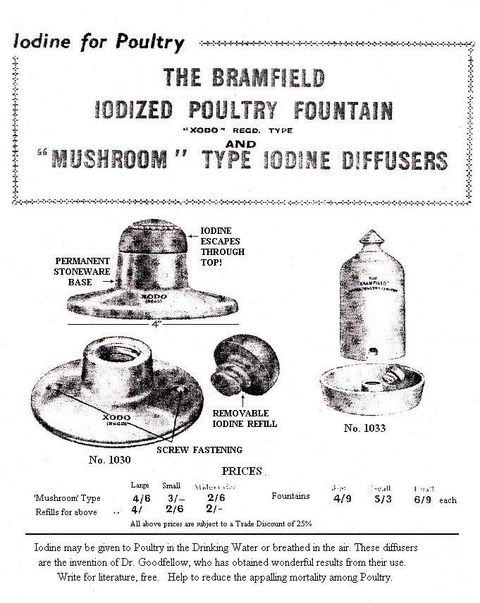

Dr. Goodfellow has the degree of porosity of the clay, used for the lockets, under absolute control. The lockets, brooches & buttons diffuse some half to one grain of iodine per week for, 3 to 6 months.

The larger candles & the 'mushroom' type diffuser will prove effective for about a year. The latter type, which is fitted in Chesterfield Corporation buses, consists of an iodine filled porous stopper, which screws into a holder. In this way the stoppers may be replaced when the iodine content has been diffused at the end of 12 months. Iodine diffusers are also being fitted throughout the buildings of the Chesterfield Picture House Ltd.

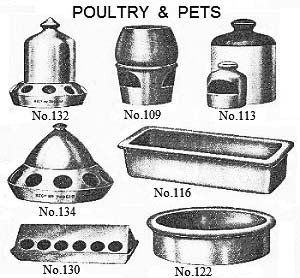

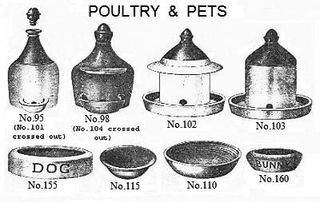

The firm has also produced & patented a fowl fountain, which has been designed to give the requisite amount of iodine without trouble: It's an ordinary bell-shaped fountain with the saucer, but in the latter & forming part of it is a porous bottle with iodine firmly secured inside.The bottle is easily recharged with iodine.

How They're Made

A fluid mixture of clay & water is poured into absorbent moulds, & allowed to set. The rough lockets are then removed from the moulds & trimmed by hand. After glazing, a girl scrapes the glazed surface from the design to permit the exit of iodine. The lockets are then 'fired', & are afterwards filled with solid iodine, hermetically sealed, & wrapped in cellophane.

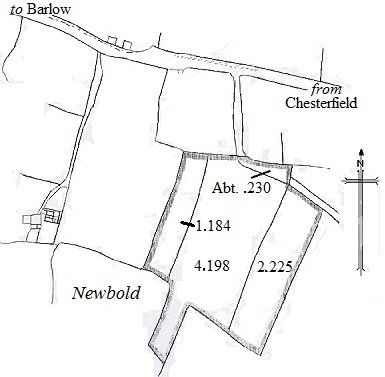

The clay used is Tupton clay, of a superior quality, from the firm's own pit. Different clays vary in plasticity, & in the hardness, colour & texture of the finished product, through an extremely wide range. The clay is first ground & then thrown into a large steel vat, in the centre of which revolves a shaft with powerful arms. Water is added & the clay is mixed into a 'cream', or 'slip'. When the 'slip' has reached the requisite degree of fineness, it is run off from the vat & sifted to eliminate all foreign matter. Thence it passes in a liquid state, into wells, & from these it is pumped into clay presses, which press out the water.

The next stage is the 'pug' mill where it is needed into a uniform consistency. It is now in a workable condition.

Some types of pottery are 'thrown' on a potter's wheel, & others are made by pressing & moulding. There is also a machine method of manufacture termed 'jollying'. 'Casting' is the latest process, & is now largely used in these works.

In the 'throwing' method a girl weighs out the clay & passes it to the potter who slaps it onto his wheel, which is a horizontal, revolving disc, pivoted on a central point. With a dexterity & swiftness, the craftsman shapes it & fashions it into a symmetrical & perfectly proportioned pot. Some pots are roughly shaped on the wheel & partly dried before being finished on a second visit to the wheel.

'Jollying' is a much newer method. The clay is placed in rotating moulds, & the girls in charge of the machines gauge the moment when the proper dimensions are reached. These are finished off on lathes.

After drying, the vessels are glazed by dipping or spraying – the latter method will soon be exclusively employed in these works.

The last stage is the 'firing.' The vessels are placed in 'saggars' – fire-clay receptacles which are passed into the kilns & baked.

The vessels have now only to be tested for flaws.

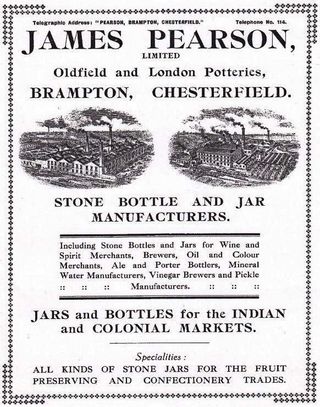

The Oldfield kiln flats at Brampton Moor are mentioned in a book of 1636, & the present pottery dates back over 100 years. Mr. James Pearson was the founder of James Pearson Ltd. & the present managing director, Dr. Goodfellow, has been associated with the business since the founder's death.

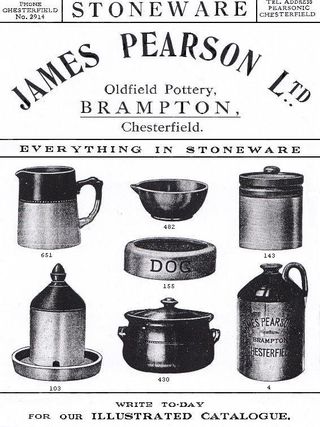

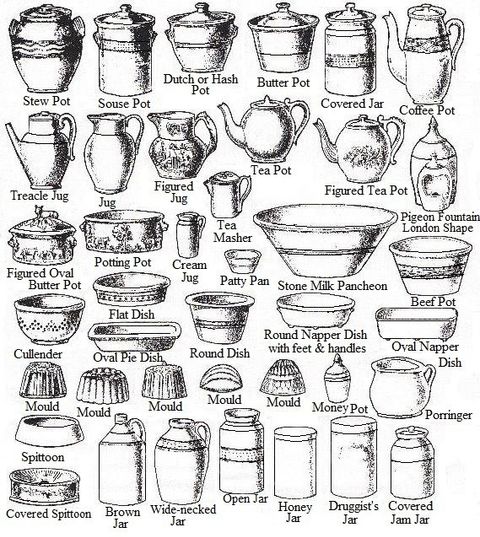

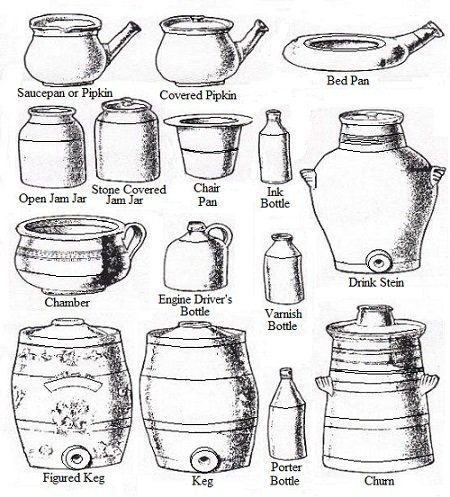

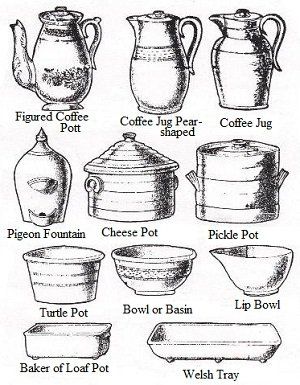

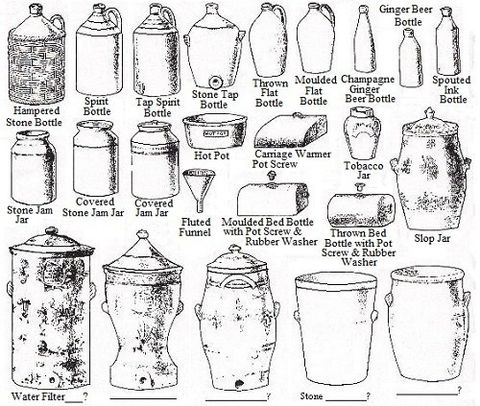

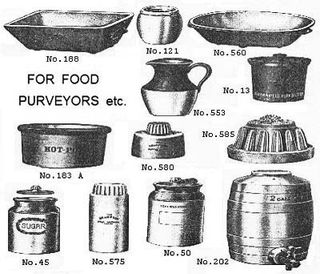

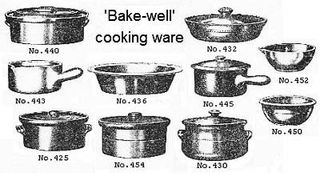

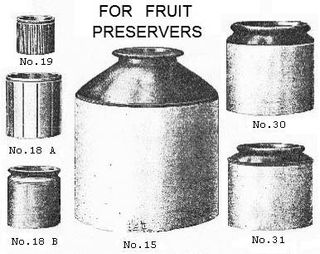

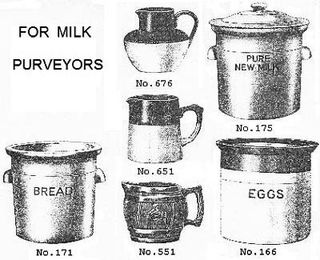

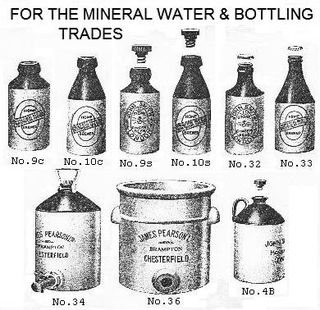

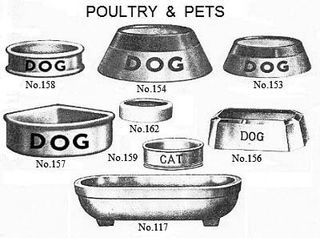

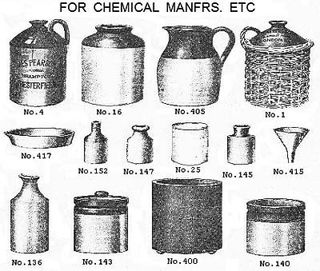

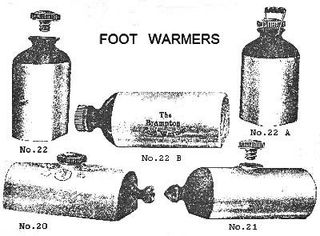

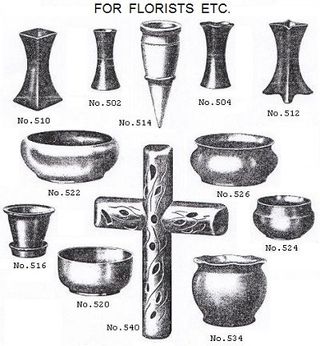

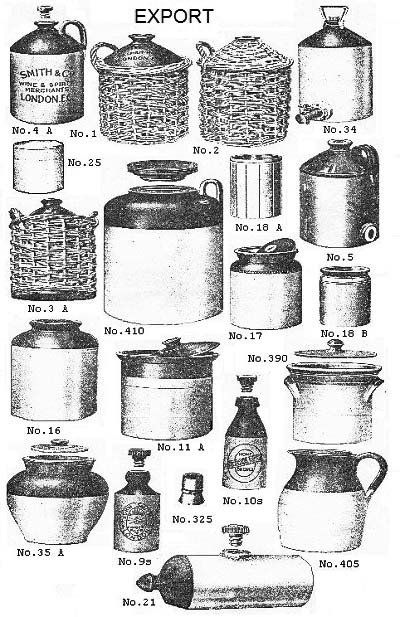

James Pearson Ltd. are reviving the production of the old Toby jugs, which are being made from the moulds used by the pottery 70 years ago. Among the specialities of the firm may be mentioned the 'Bake-well' cooking ware, which, with ordinary care, may be used on an open flame. In addition to all kinds of cooking ware, jugs, bread pancheons, basins, jam jars, & jars for fruit preserving James Pearson Ltd also make a variety of bottles for the wine, spirit, mineral water & vinegar trades; foot-warmers; special stoneware of all descriptions for export; drinking fountains & bowls for poultry & pets; acid jars & other stoneware for chemical manufacturers; & bulb bowls, vases & cemetery crosses for florists.

Back at Messrs. Pearson & Co. the marriage of its Works Manager Mr. Geoffrey Walter Morton Rees, to Miss Alice Mary Senior, took place on Satuday the

31st of October 1936, at Upper Chapel Sheffield. Mr. Rees is the elder son of of Mr & Mrs W.J. Rees; Mr W. J. Rees MSc., F.I.C., is president of the Refractories Association of Great Britain; & Head of the Refractories Department of Sheffield University. Miss Senior is the daughter of Mr & Mrs J.W. Senior of Sheffield.

By

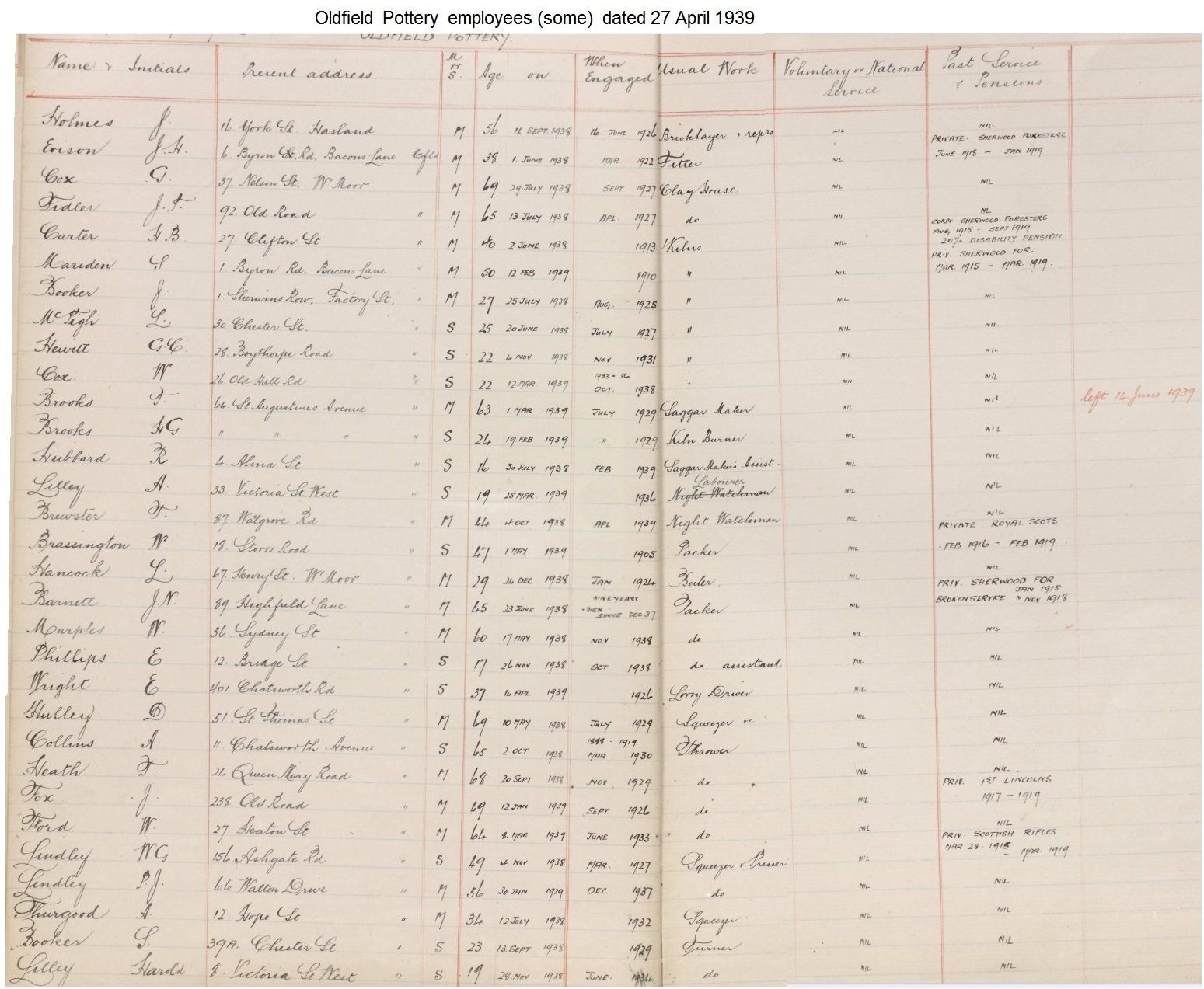

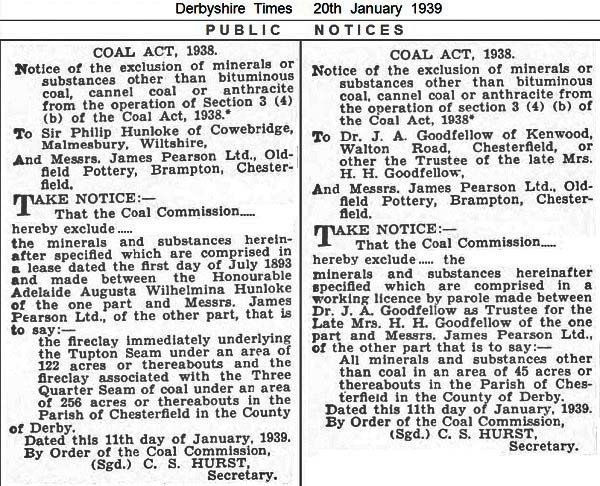

19th May 1939 the Oldfield Pottery had changed hands. It had been in difficulties & needed fresh capital to modernise & carry on the business. Dr. Goodfellow had kept the firm afloat with the sale of iodised products in recent years but it was not enough. It was arranged that the control & management of the stoneware business will pass into other hands; & the iodine department will be completely separated from the stoneware business. Dr. Goodfellow's association with the business will be one of an Honourary Consultant only.

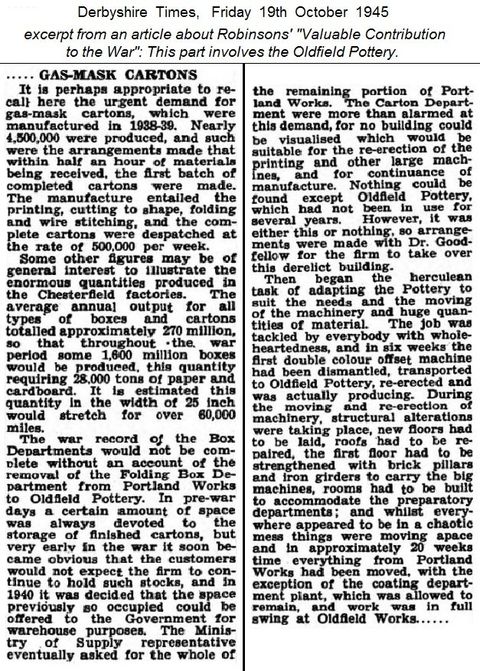

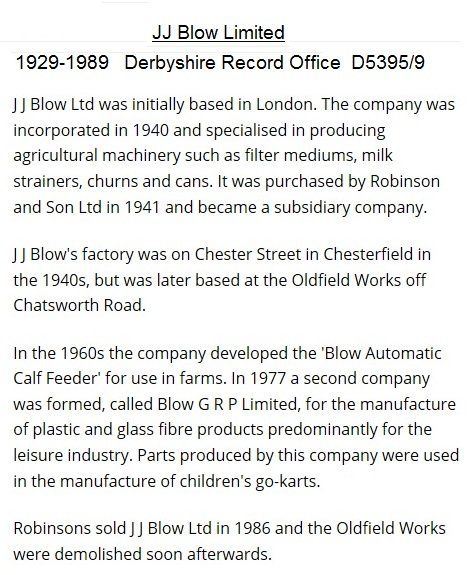

The newspaper articles below, dated 1941 & 1945, shows that Robinsons took over the Oldfield Pottery for their Folding Box Department & storage; then it was later used by a subsidiary of Robinsons, J J Blow.

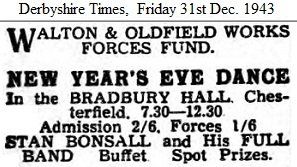

Dances were held on a Friday night in aid of the forces. I've also put an advert for the one that was held on New Year's Eve 1943 below.

Dr. James Anderson Goodfellow, of Kenwood, 175 Walton Rd., died on the

1st May 1950; his wife Harriet Helen having died in 1929. His effects were £5,637 14s. 4d.

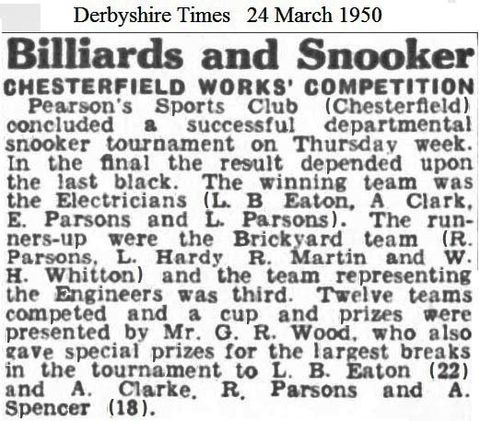

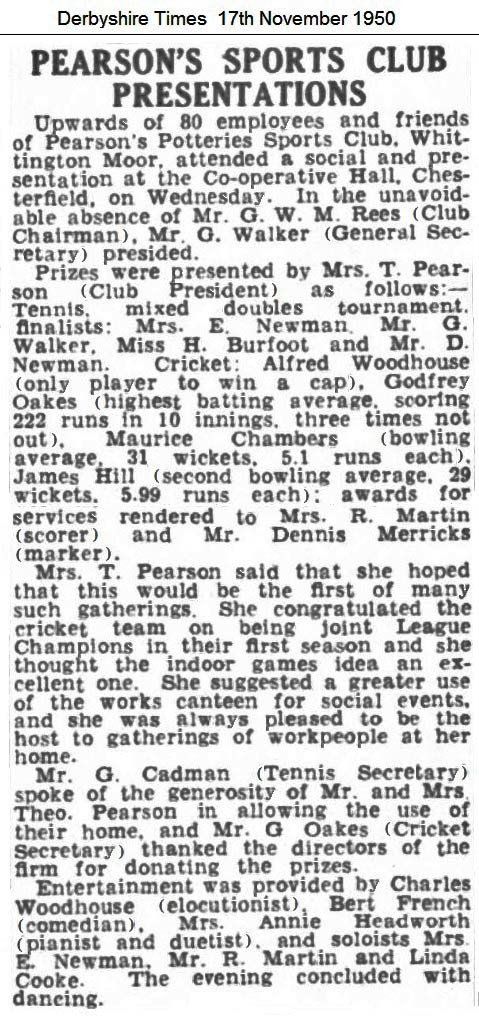

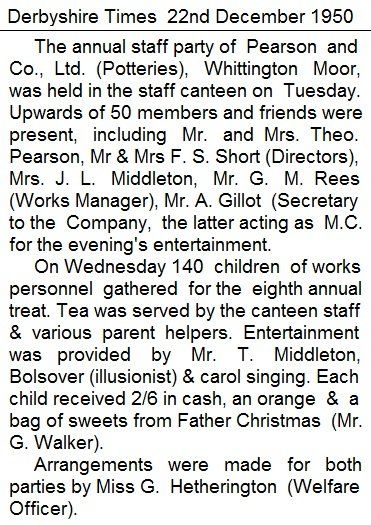

The employees of Messrs. Pearson & Co., Whittington Moor were more of a community with sport playing a large part. There were teams for football, cricket, bowling & darts etc.

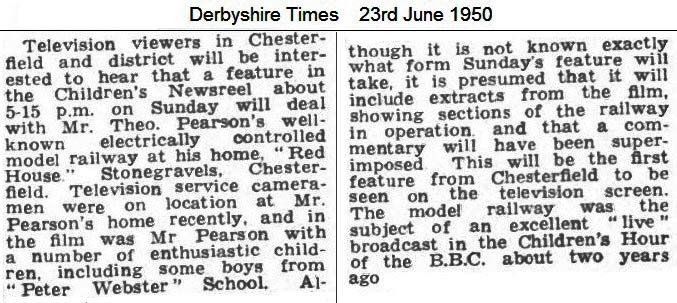

The Pearson Pottery Bowling club played on the bowling green at the home of Theo. Pearson at Red House, Stonegravels; & there was a Pearson sports ground.

The Times 21st August 1964

NEW POTTERY MERGER

The pottery firm of Pearson (Chesterfield) has acquired a controlling interest in Abbeydale New Bone China.

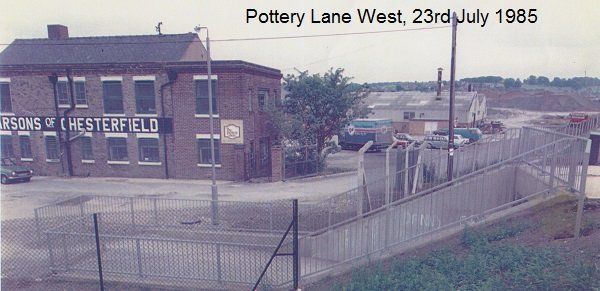

By September 1983 Pearson & Co., Whittington Moor hadn't been doing well for at least a year & was facing receivership. It had been in the hands of the receiver for nine months & the workforce had gone down from 240 to 57. The last 'Pearson' to be in charge was Theophilus Pearson, son of Johnson Pearson & he died in 1959.

By 1991, however, Pearsons had passed into the hands of the Staffordshire Moira Pottery; & by June 1994 the firm of Pearsons and Moira went into voluntary liquidation & the assets were bought by Swindon-based potters Cloverleaf. The final 65 staff were told they'd been made redundant by Liquidators Coopers Lybrand of Nottingham. Pearsons' machinery was moved to Cloverleaf Group's potteries, T. G. Green at Church Gresley.

Information c/o the Derbyshire Times & Reflections magazine May 2007.

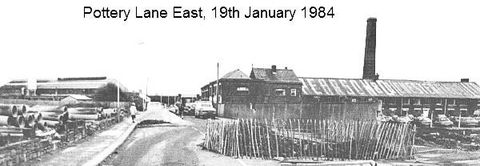

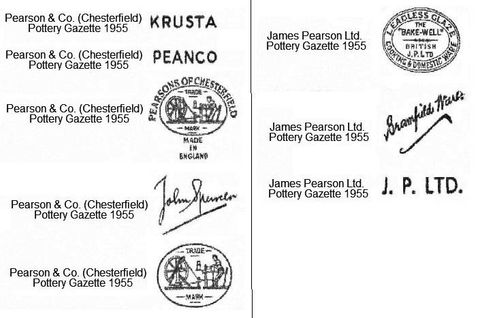

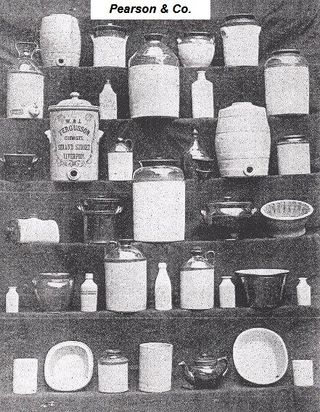

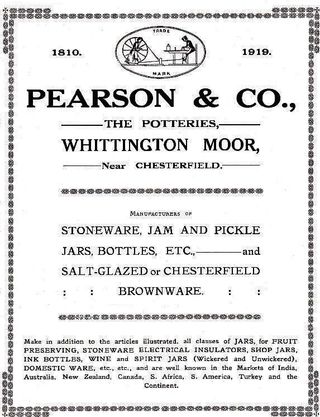

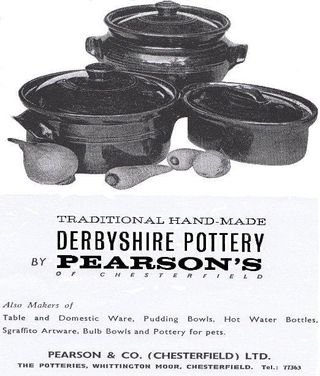

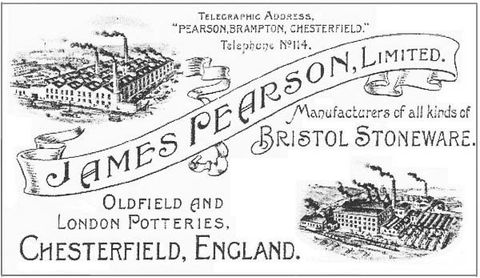

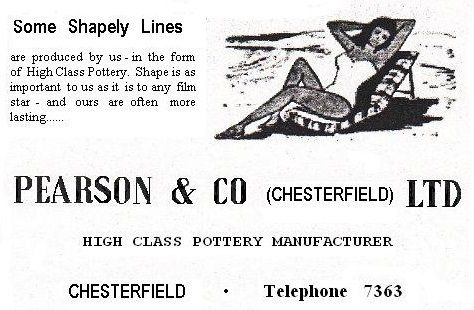

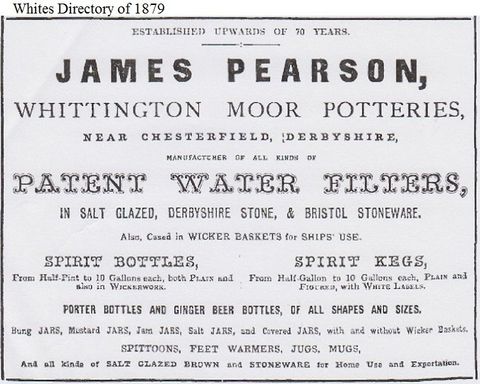

To finish my blog on the Pearson Potteries are a number of adverts each firm used, pottery that was made, & trademarks.

The majority of illustrations came from the Local studies Department of the Chesterfield Library; which also holds information on the potteries.

They're mixed images of Pearson & Co. Whittington, & James Pearson, Brampton.

Pottery products.

James Pearson Products.

End